Selective Laser Melting – SLM

As with all printing processes, the desired model must first be translated into “the language” of the respective printer. For this purpose, there is often device-specific software or software from third-party suppliers that must be fed with the corresponding data of the device. This software builds up the desired model in layers and defines all process parameters for the upcoming print. For example, the orientation in space, support structures used or the layer height or power of the laser are defined here. This file is then transferred to the printer and a new print job can be started.

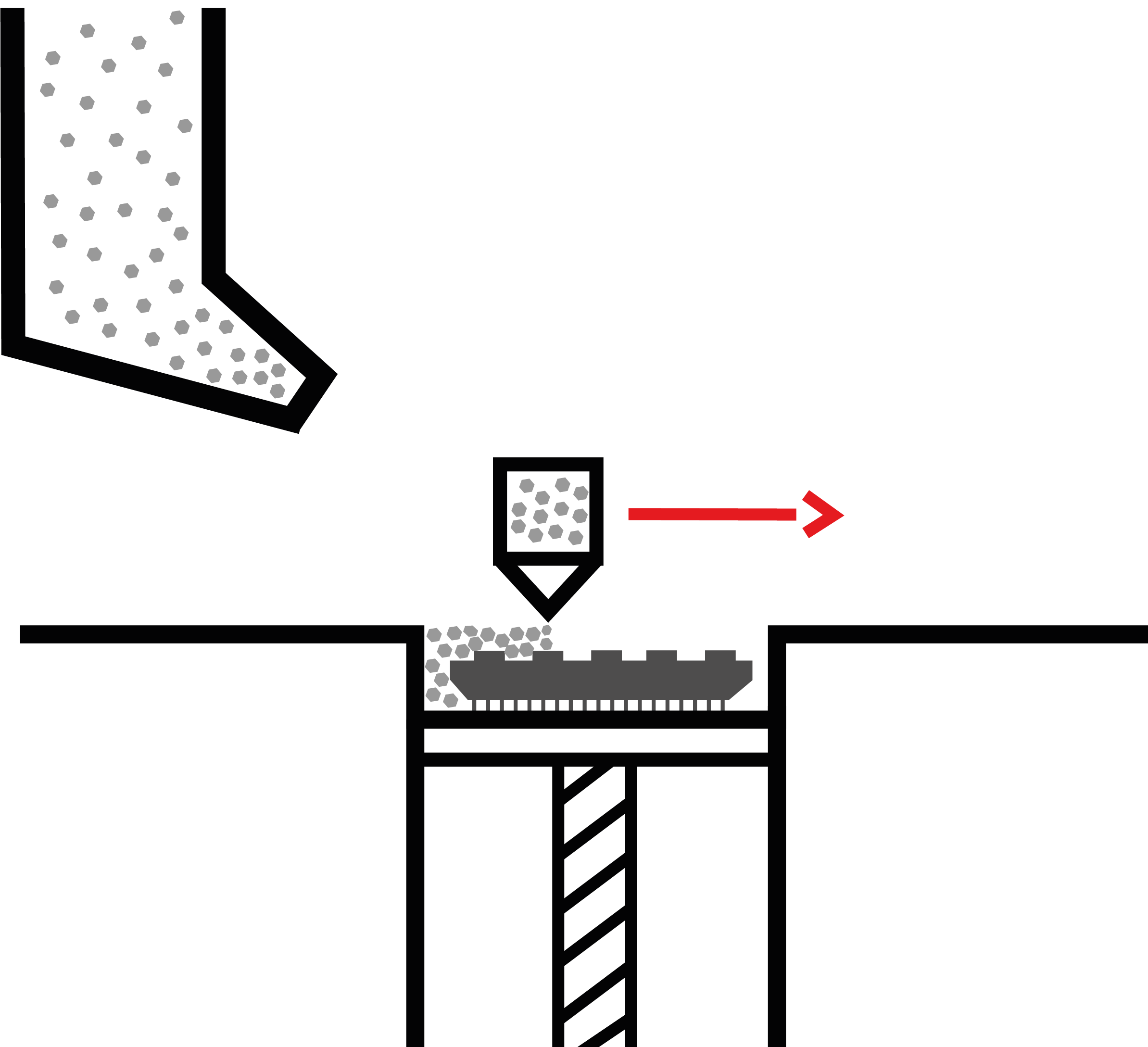

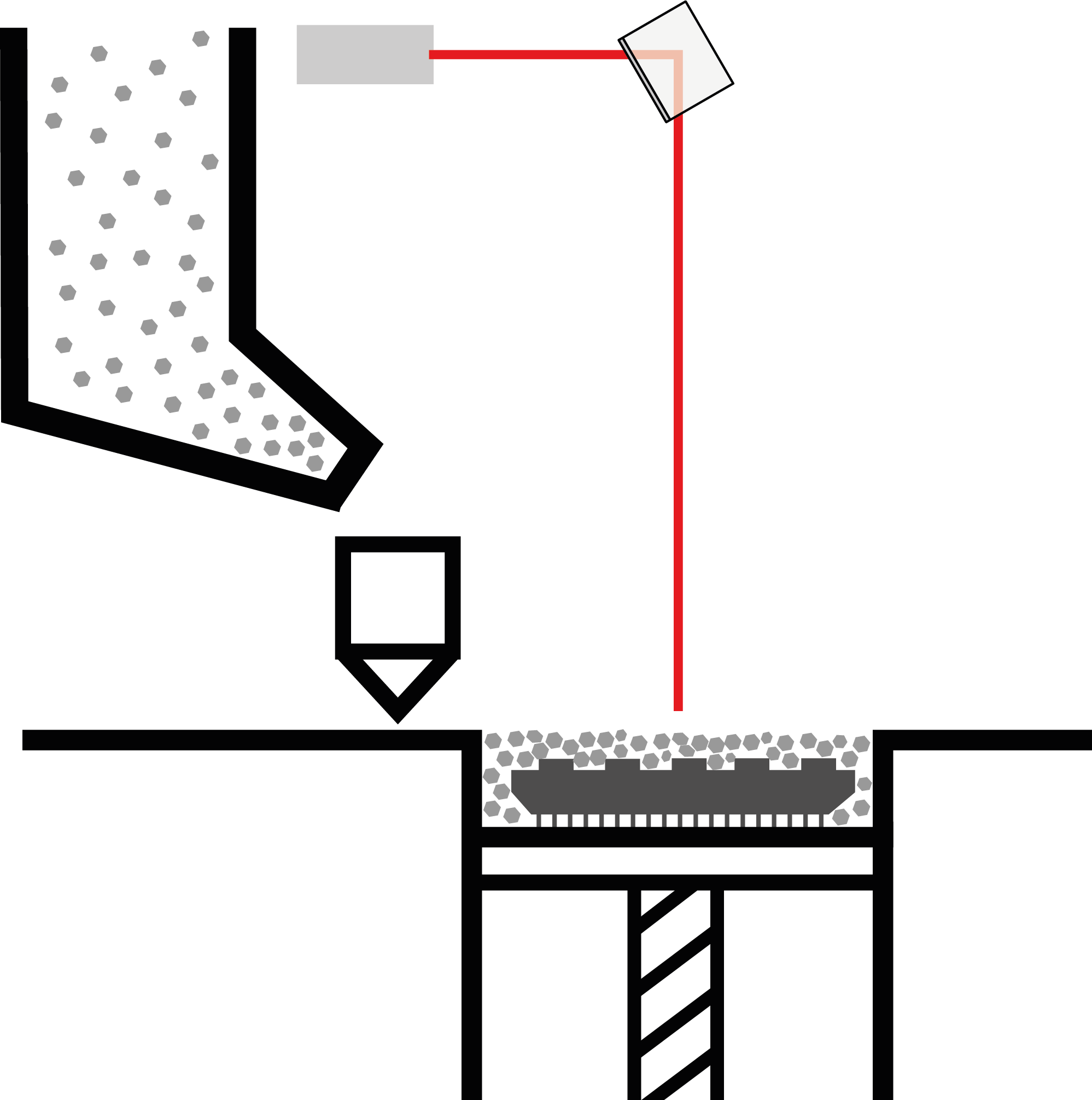

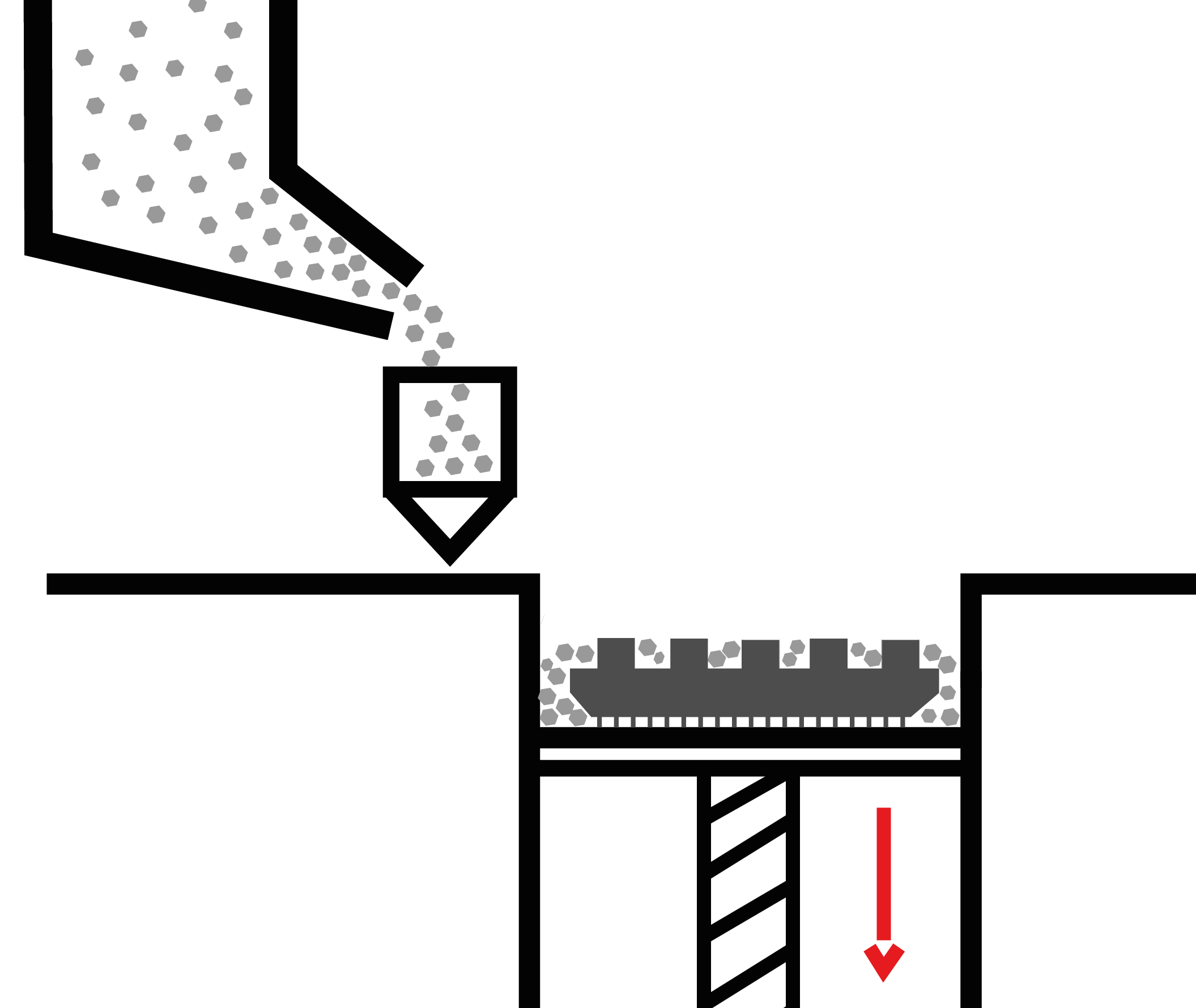

In most cases, the pressure chamber is first inerted to prevent oxidation during the process. Once the chamber is inerted, the gas is passed over the print bed to be exposed like a protective layer. This allows the resulting flue gas to be minimized and removed. This is followed by three recurring process steps (see Fig. above):

• Powder application

• Exposure (Scanning)

• Moving the table by the layer height

This procedure is repeated until the desired model is completely generated. It is important to know that the desired geometry is welded onto the base plate, either directly or with a certain distance (a few millimeters) using support structures. The difference between the two is determined by the part geometry and orientation, as well as the post-processing. In the SLM process, support structures are basically necessary to dissipate the heat introduced into the part and minimize distortion based on this heat. After the printing job is finished, the entire working area must be cleared of any powder that has not melted. This powder is reprocessed and can be fed back into the printing process. The result is then a printing plate with a welded-on model. This must then be separated from the plate and prepared in various post-processing steps. Depending on the design of the supports used, these have to be removed with more or less effort in post-processing. The base plates must be mechanically processed after each construction to remove the old supports completely and to provide a flat surface for the next use.