Metrology

You can find more information about the equipment used in the following accordion. If you have any further questions, please feel free to contact us.

Zeiss Comet L3D 5M

Ways to do this:

• Initial sample inspection report

• Reverse engineering

• Production monitoring

The accuracy of the measuring system is 30-80 μm, depending on the measuring field used.

Location: Environmental Campus Birkenfeld

Zeiss T-Scan CS

Ways to do this:

• Capture large objects

• Reverse engineering

The accuracy of the system is in the range of 50μm±50μm/m.

Location: Environmental Campus Birkenfeld

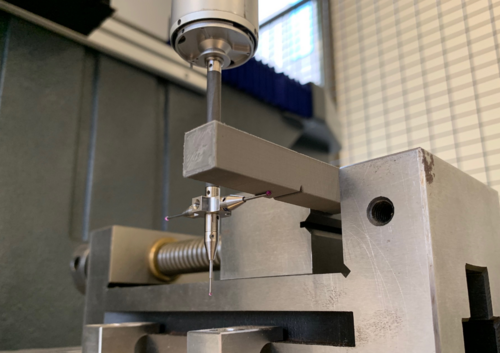

Zeiss DuraMax

The DuraMax from Zeiss is a coordinate measuring machine to measure surfaces in all 3 dimensions. Measurements with very high accuracies can be achieved via the single point measurements. Measurements can be performed both manually and CNC supported.

The length deviation is 2.7 µm+ L/250 (at 18-26°C) and the measuring range is 500x500x500 mm.

Ways to do this:

• Initial sample inspection report

• Production monitoring

Location: htw saar